Harog Graphite Bipolar Plates: Small Component, Massive Power

Why Our Graphite Bipolar Plate Steals the Spotlight

What determines whether a fuel cell stack lasts 1,000 hours or 10,000 hours? In many cases, the answer lies in the quality of the bipolar plate. Our Graphite Bipolar Plate is engineered for high conductivity, exceptional corrosion resistance, and long-term structural stability in demanding hydrogen fuel cell environments. Manufactured from high-purity graphite materials with precise flow field machining or composite reinforcement options, it ensures efficient gas distribution, low contact resistance, and reliable sealing performance. Discover how the right graphite solution can elevate your fuel cell performance—and why material choice makes all the difference.

Product Center

Built to Last, Designed to Lead

Advanced Material Engineering for Long-Term Reliability

Built on our Composite Isostatic Graphite Bipolar Plate and Composite Flexible Graphite Bipolar Plate technologies , our solutions combine high-purity graphite with optimized composite structures to deliver exceptional corrosion resistance and electrochemical stability. Unlike metallic plates that depend on surface coatings, our graphite-based design inherently resists oxidation in acidic PEM environments, minimizing degradation risks over long operating cycles.

Structural Versatility with Sustainable Lifecycle Value

Our product portfolio includes both high-density isostatic graphite plates for maximum mechanical strength and lightweight composite flexible graphite plates for mobility-focused applications . This dual-technology approach allows customers to optimize stack weight, durability, and cost based on specific application demands. In addition, the composite thermoplastic-based structure supports material recovery and reprocessing, contributing to recyclability and reduced environmental impact.

Technical Specifications

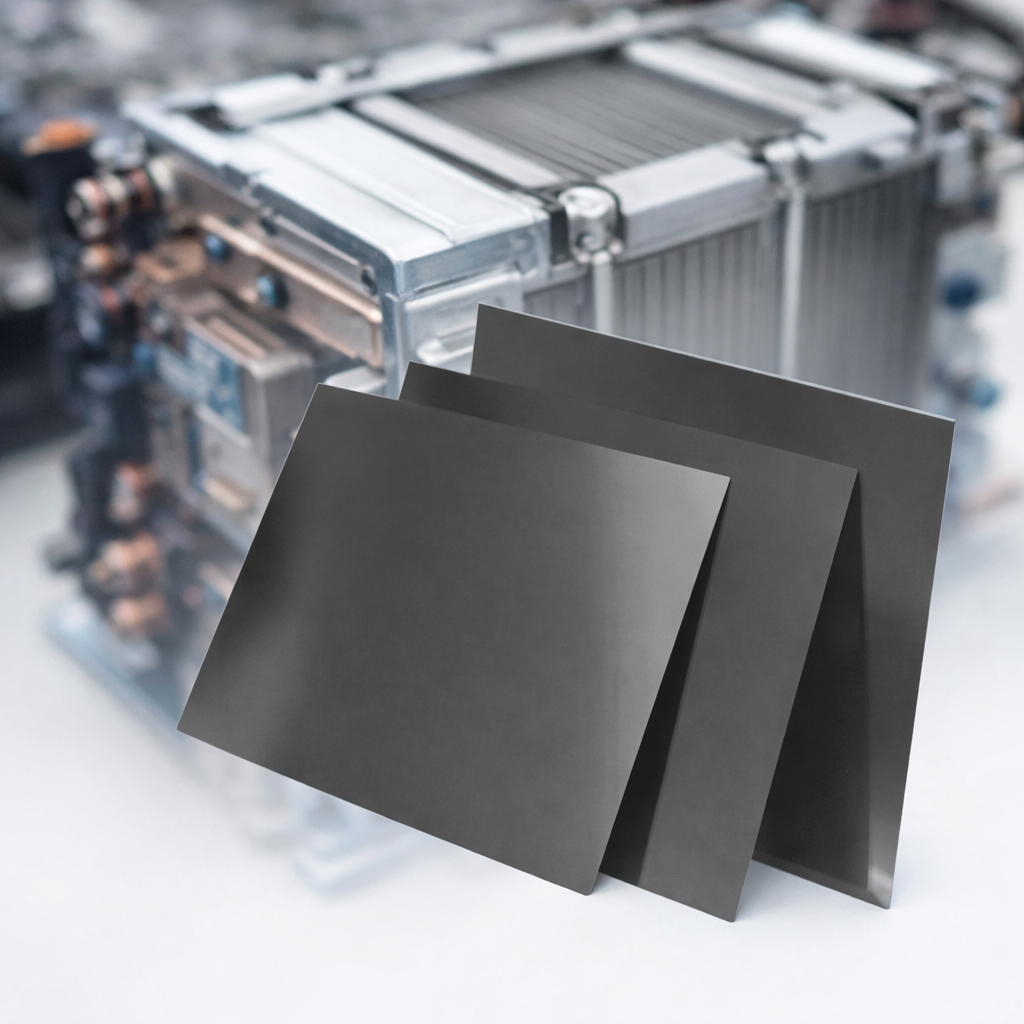

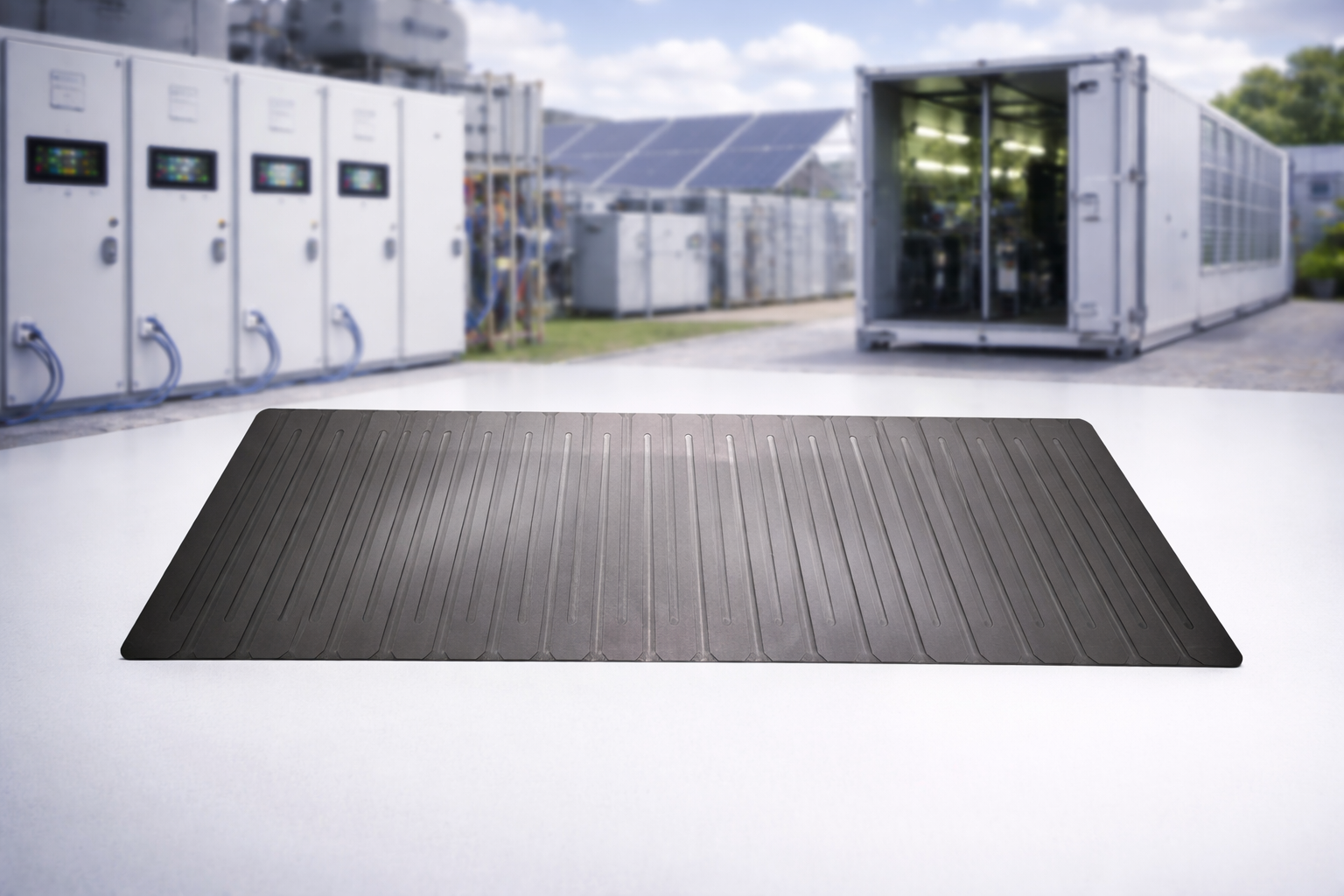

Flexible Graphite Bipolar Plate

Designed for lightweight and adaptable PEM fuel cell stacks, combining expanded graphite with reinforced composite structure.

Density: ~1.6–1.8 g/cm³

Electrical Conductivity: High in-plane conductivity with low contact resistance

Thickness Range: 0.8–2.0 mm (customizable)

Key Advantage: Flexible structure improves sealing performance and stack adaptability

Isostatic Graphite Bipolar Plates

Manufactured from high-density isostatic pressed graphite and precision CNC-machined for high-performance fuel cell systems.

Density: ~1.8–1.9 g/cm³

Compressive Strength: High, suitable for strong stack clamping forces

Electrical Conductivity: Excellent bulk conductivity

Key Advantage: Superior structural stability for long-life applications

Carbon-Plastic Graphite Bipolar Plates

Carbon-filled thermoplastic composite plate designed for scalable and lightweight fuel cell production. Density: ~1.5–1.8 g/cm³

Manufacturing Method: Compression or injection molding

Electrical Conductivity: Stable and suitable for PEM requirements

Key Advantage: Lightweight structure with recyclable composite material

Contact Us

Where Our Graphite Bipolar Plates Get to Work

Why Choose Us

Specialized Focus on Graphite Bipolar Plates

We concentrate on advanced carbon and graphite materials, with Graphite Bipolar Plate development as a core direction of our hydrogen energy strategy. This specialization allows us to continuously refine material formulation, structural design, and processing techniques, ensuring stable conductivity, low permeability, and long-term durability in demanding PEM fuel cell environments.

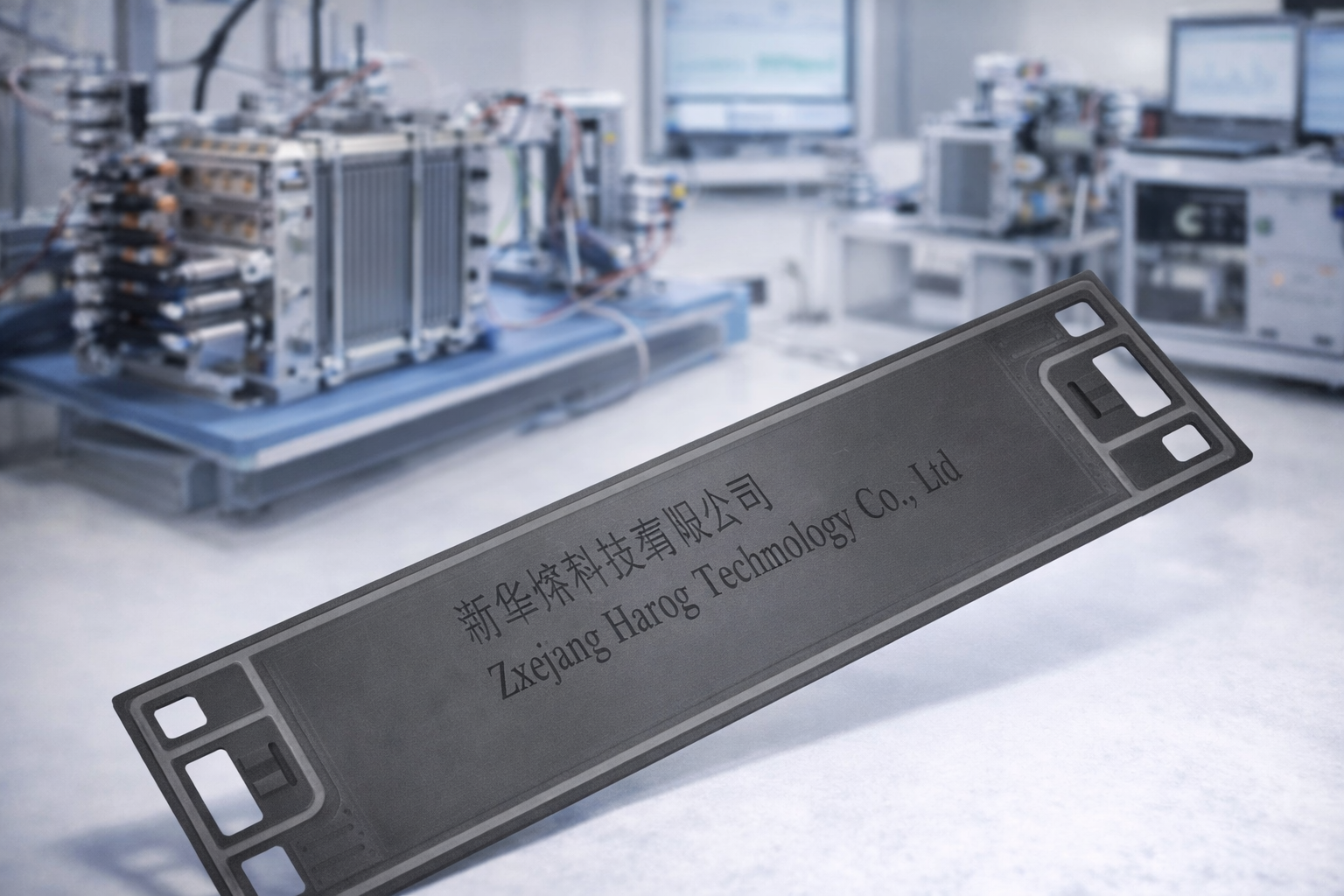

Strong R&D and Engineering Capability

Backed by a dedicated technical team and independent development capabilities, we continuously optimize composite structures, flow field precision, and mechanical performance. Our engineering-driven approach enables us to provide customized graphite bipolar plate solutions tailored to stack architecture, power density targets, and specific application requirements.

Scalable Manufacturing with Quality Control

With modern production facilities and integrated manufacturing processes, we ensure consistent material properties and dimensional accuracy across every batch. From raw graphite processing to precision machining and composite molding, strict quality control supports reliable performance in automotive, stationary, and portable hydrogen systems.

Commitment to Hydrogen Energy Sustainability

Our graphite bipolar plates are designed not only for performance but also for long-term environmental responsibility. By leveraging durable graphite materials and recyclable composite structures, we support cleaner hydrogen technologies while helping customers reduce lifecycle costs and improve system sustainability.

Contact Us

Looking for a reliable graphite bipolar plate partner for your hydrogen fuel cell project? Contact our team today to discuss your technical requirements and receive a customized solution tailored to your application.

FAQs

Related Blogs

-

Recently, the conference on building a first-class innovation ecosystem and creating the most competitive business environment in the province was held in Hangzhou. At the conference, the list of winners of the 2024 Zhejiang Provincial Science and Technology Awards was officially announced, commendi

Recently, the conference on building a first-class innovation ecosystem and creating the most competitive business environment in the province was held in Hangzhou. At the conference, the list of winners of the 2024 Zhejiang Provincial Science and Technology Awards was officially announced, commendi

Keep In Touch With Us

Stay connected with us to explore the latest developments in Graphite Bipolar Plate technology and hydrogen fuel cell innovation. Whether you need technical consultation, customized solutions, or industry updates, our team is ready to support your next project with reliable expertise and responsive service.

Mob:+86-15613141041

E-mail:filo.li@harog.net