Views: 0 Author: Site Editor Publish Time: 2026-01-06 Origin: Site

Heavy-duty trucks are vital for global freight but are also major contributors to CO2 emissions. In Europe alone, road freight accounts for almost 30% of mobility sector emissions. As the world pushes toward cleaner energy, fuel cells offer a promising solution for reducing these emissions.

In this article, we will explore why Fuel Cell Graphite Bipolar Plates are essential for heavy-duty trucks. You will learn how these plates enhance fuel cell performance, making them more efficient and environmentally friendly for the transportation sector.

Heavy-duty trucks require power systems that can operate efficiently in demanding conditions. Fuel cells used in these trucks must provide long-lasting performance while withstanding harsh environments. Components like graphite bipolar plates are key to ensuring durability and reliability over extended hours of operation.

Key demands for heavy-duty truck fuel cells:

Demand | Description |

Mechanical stress | Endure physical wear and tear. |

High temperatures | Operate in extreme heat. |

Corrosive exposure | Resist corrosion for efficiency. |

Extended operation hours | Withstand continuous use without degradation. |

Durability, reliability, and longevity | Ensure long-term success. |

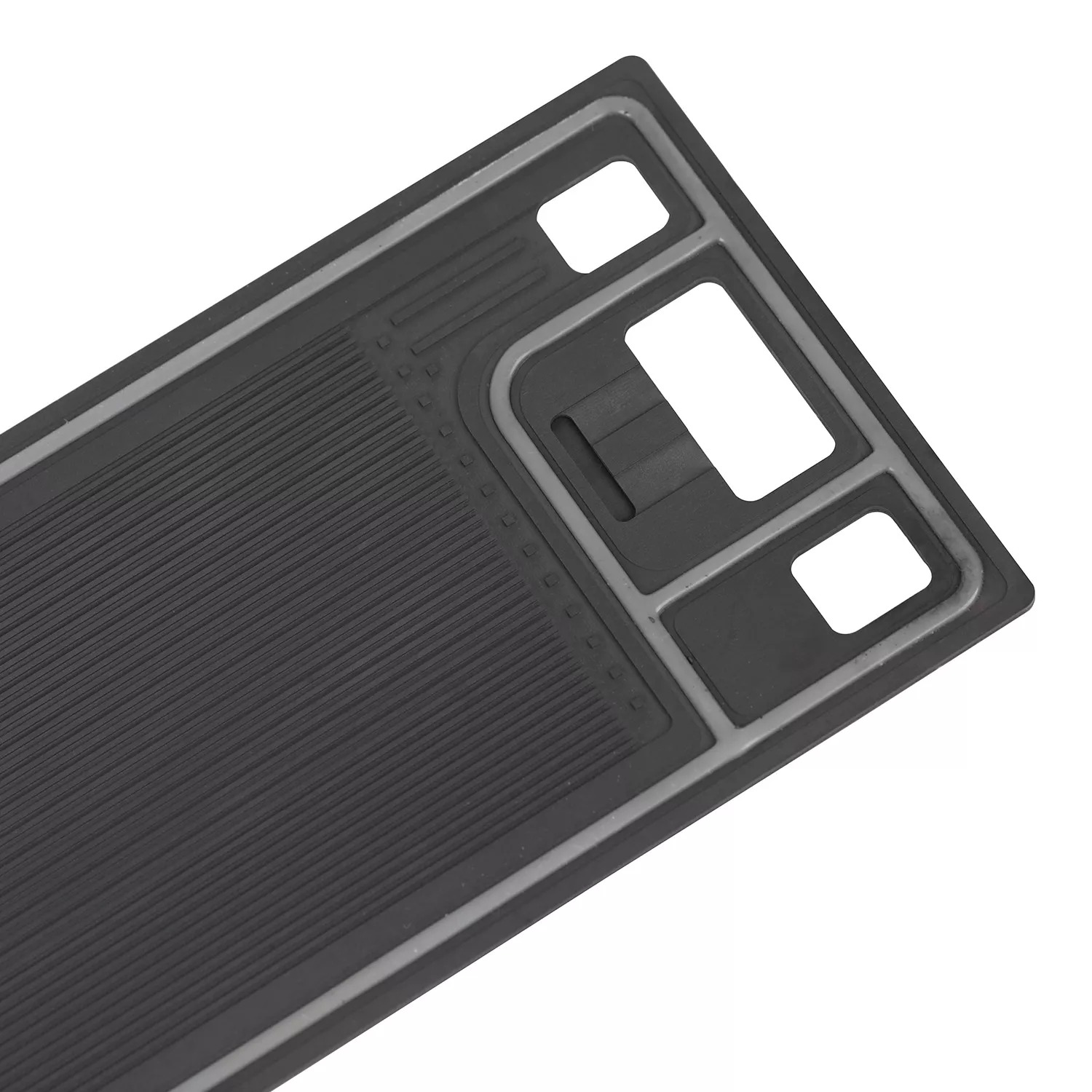

Graphite bipolar plates are specifically designed to meet these rigorous demands. Unlike metal plates, which require expensive coatings to protect against corrosion, graphite is naturally corrosion-resistant. This resistance is essential for fuel cells, especially in harsh, high-temperature environments like those found in heavy-duty trucks. Additionally, graphite's durability ensures that these fuel cells can last for tens of thousands of hours, making them suitable for long-term operations in the transportation sector.

Fuel cell-powered trucks equipped with graphite bipolar plates have already proven successful in real-world applications. These trucks benefit from enhanced operational efficiency and reduced emissions, as well as quicker refueling times, longer range, and minimal downtime due to the robust nature of the graphite bipolar plates. As fleets transition to cleaner technologies, graphite plates ensure that fuel cells remain viable for the long-term.

Examples of real-world applications:

● Hydrogen fuel cell trucks improving operational efficiency in long-haul transportation

● Quicker refueling times and longer range due to graphite bipolar plates

● Reduced downtime and increased reliability in commercial fleet operations

Graphite bipolar plates excel in environments that challenge other materials. The internal workings of fuel cells, especially those used in heavy-duty trucks, operate under acidic conditions at high temperatures. In these settings, traditional metal plates often corrode or degrade, which can shorten the lifespan of the fuel cell. Graphite, on the other hand, is chemically inert and maintains its integrity under these conditions, ensuring a longer operational life for the fuel cell system.

In fuel cell applications, efficient heat management and electrical conductivity are crucial. Graphite plates have exceptional thermal and electrical conductivity, which helps distribute heat and electricity evenly across the system. This enables better power output and improves the efficiency of fuel cell systems in heavy-duty trucks. For instance, high-conductivity graphite bipolar plates optimize the electrochemical reactions that take place in the fuel cell, leading to enhanced overall performance.

One of the most significant advantages of graphite bipolar plates is their ability to withstand wear and tear over extended periods. Unlike metals, which may degrade over time, graphite maintains its structural integrity and efficiency. This is especially important in heavy-duty truck fuel cells, which are expected to perform for tens of thousands of hours. The durability of graphite ensures that fuel cells in these trucks remain operational for long periods, minimizing maintenance costs and reducing downtime.

Graphite bipolar plates also offer a more cost-effective solution compared to their metal counterparts. The production process for graphite plates is simpler and less expensive, particularly for high-volume manufacturing. The materials required for graphite plates are more affordable, and the manufacturing process is less complex, which helps reduce overall production costs. As fuel cell technology becomes more widespread in the heavy-duty transport sector, the cost advantages of graphite plates will help make this technology more affordable for large-scale deployment.

Advantage | Key Benefit |

Corrosion Resistance | Maintains integrity in harsh environments. |

Thermal and Electrical Conductivity | Enhances power output and efficiency. |

Durability and Performance | Withstands wear and tear over long periods. |

Cost-Effectiveness | Reduces production costs for large-scale use. |

While metal plates might offer advantages in certain areas, graphite plates are the more cost-effective choice for fuel cells in heavy-duty trucks. Graphite plates are easier to manufacture and do not require costly protective coatings like metal plates. This makes them a more affordable option for producing high-performance fuel cells that can be used in the commercial fleet sector.

As the demand for hydrogen fuel cells increases, economies of scale will make graphite bipolar plates even more cost-effective. The mass production of graphite plates allows for cost reductions across the supply chain, making fuel cells a more affordable option for large commercial fleets. This scalability is essential for the widespread adoption of hydrogen-powered trucks, which are expected to play a significant role in the future of sustainable transportation.

Water management is a critical aspect of fuel cell performance. As hydrogen reacts with oxygen in the fuel cell, water is produced as a byproduct. If not managed properly, this water can accumulate and flood the fuel cell, reducing its efficiency. Graphite bipolar plates are designed to manage the water byproducts efficiently. Their structure allows for effective drainage and distribution of water, ensuring the fuel cell maintains optimal performance.

In heavy-duty trucks, where fuel cells are expected to operate for extended periods, proper water management is even more crucial. If a fuel cell becomes flooded, it can lead to reduced power output, shorter lifespan, and increased maintenance costs. Graphite plates help to prevent flooding and maintain the fuel cell's efficiency, ensuring that trucks can continue to operate smoothly without interruption.

Recent innovations in hybrid compound films for bipolar plates combine the best properties of metals and graphite. These films enhance the overall performance of fuel cells by improving their durability, conductivity, and resistance to corrosion. By integrating advanced materials, such as hybrid compounds, fuel cell manufacturers can create even more efficient and reliable systems for heavy-duty applications.

Modern manufacturing techniques, including laser technology, are revolutionizing the production of graphite bipolar plates. These technologies allow for the precise cutting and shaping of plates, improving their performance and reducing the likelihood of defects. Precision manufacturing ensures that each plate meets the strict specifications required for heavy-duty applications, contributing to more reliable and durable fuel cell systems.

Hydrogen fuel cells offer a zero-emission alternative to diesel engines in heavy-duty trucks. By using hydrogen as a fuel source, fuel cells produce only water vapor as a byproduct, significantly reducing CO2 emissions. Graphite bipolar plates play a crucial role in this process by ensuring the fuel cells operate efficiently over extended periods, making them ideal for heavy-duty transportation applications.

Fuel cells, powered by graphite bipolar plates, are not limited to heavy-duty trucks. They are also used in other sectors, such as maritime propulsion systems, material handling equipment, and backup power generators. These versatile fuel cell systems provide clean energy solutions for a variety of industries, further cementing the role of graphite bipolar plates in the broader push toward sustainable energy solutions.

Fuel cell technology, bolstered by innovations like graphite bipolar plates, is set to transform the future of clean energy transportation. As the world moves toward a more sustainable future, hydrogen-powered fuel cells will play an increasingly important role in decarbonizing heavy-duty transportation, offering an efficient and eco-friendly alternative to traditional fuels.

Application | Benefit |

Heavy-Duty Trucks | Zero-emission, efficient transportation. |

Maritime Propulsion Systems | Clean energy for shipping industries. |

Material Handling Equipment | Eco-friendly power for industrial sectors. |

Backup Power Generators | Reliable, sustainable energy solutions. |

Fuel cell graphite bipolar plates are crucial for hydrogen fuel cells in heavy-duty trucks. Their corrosion resistance, high conductivity, and durability ensure reliable, long-term performance in challenging environments. These plates help reduce emissions and operating costs while providing efficient power for trucks.

Looking ahead, graphite bipolar plates will drive the adoption of hydrogen-powered trucks, offering a cleaner alternative to diesel vehicles. Zhejiang Harog Technology Co., Ltd. provides these high-quality plates, helping companies transition to a more sustainable transportation future.

A: Fuel cell graphite bipolar plates are key components in hydrogen fuel cells used in heavy-duty trucks. They provide corrosion resistance, high conductivity, and durability, ensuring efficient operation and long-term performance in challenging environments.

A: Graphite bipolar plates improve fuel cell performance by offering high electrical conductivity and optimal heat dissipation. This ensures consistent power generation in heavy-duty truck power systems, reducing emissions and operating costs.

A: Corrosion-resistant graphite plates, such as PEM fuel cell graphite plates, prevent degradation in harsh environments. This ensures the longevity and reliability of fuel cells, crucial for heavy-duty truck applications where durability is key.

A: High-conductivity graphite bipolar plates improve the efficiency of hydrogen fuel cells by ensuring better heat and electrical current distribution, enhancing overall fuel cell performance in heavy-duty trucks.

A: Yes, these plates are versatile and used in various applications like material handling equipment, maritime propulsion systems, and stationary fuel cell stacks, ensuring efficiency across industries.

A: Graphite flow field plates play a crucial role in directing the flow of hydrogen and oxygen in fuel cells, optimizing gas distribution and preventing flooding, thus enhancing fuel cell performance in heavy-duty trucks.