From phones to megawatt-hour storage farms, Li-ion cells are the common currency of electrified life. The race is on to charge faster, cycle longer and manufacture greener—goals that hinge on reusable, thermally stable and ultra-pure process vessels.

Carbon does not just store lithium; it hosts the birth of the electrode. High-density graphite crucibles cradle cathode and anode powders through 800–1,200℃ calcination, then ride roller kilns again and again without warping, spalling or dumping metallic impurities into the active material. Their light weight, inert chemistry and matched thermal expansion let producers raise kiln loading, cut energy per kilogram and move to larger-format, higher-capacity cells.

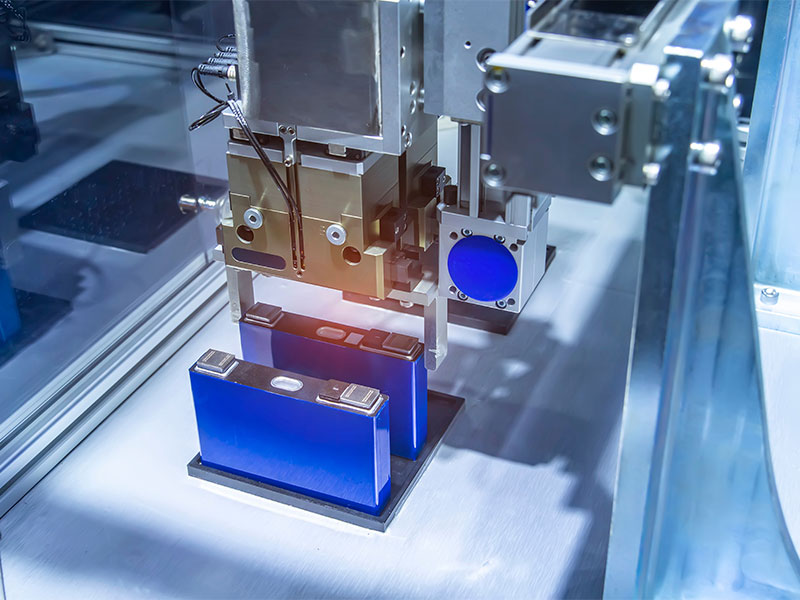

From isostatic graphite crucibles to SiC-coated setter plates, Harog Technology supplies the carbon infrastructure that turns precursor powders into performance electrodes—helping battery makers scale rapidly, waste less energy and deliver cells that charge quicker, last longer and drive the world’s electrified future.